Comprehensive Guide to Ventilation Duct Cleaning: Steps, Tools, and Safety Tips

Introduction

Ventilation duct cleaning affects more than dust bunnies and cobwebs; it touches indoor air quality, comfort, and system longevity. When debris accumulates, airflow suffers, motors work harder, and particles can be redistributed through supply registers. Although not every building needs frequent deep cleaning, periodic inspection and targeted service help reduce allergens, odors, and hot-or-cold spots. Whether you manage a busy office or live in a compact apartment, understanding methods, tools, and safe practices can help you choose a smart approach—do it yourself for small tasks, or bring in specialists for complex layouts and heavy contamination. Below, you’ll find a structured path from planning to verification, grounded in practical experience and sensible safeguards.

Outline

– Why clean ventilation ducts: health context, airflow efficiency, and building performance

– Tools and materials: inspection devices, agitation options, negative-pressure collection, filtration

– Step-by-step cleaning workflow: preparation, containment, cleaning, verification

– Safety, quality, and environmental considerations: PPE, containment, responsible disposal

– DIY or professional: cost drivers, red flags, scheduling, and a maintenance roadmap

Why Ventilation Duct Cleaning Matters: Health, Efficiency, and Building Performance

Clean ventilation ducts help a system do what it was designed to do: move air evenly, quietly, and consistently. Dust and lint form naturally as occupants shed fibers and skin cells, pets release dander, and outdoor particles ride in on shoes and open windows. Over time, loose debris can collect in return ducts and at branch lines, particularly where airflow slows. The outcome is familiar—grilles look dingy, airflow seems uneven, and some rooms lag in comfort. In mixed-use buildings, cooking aerosols, office paper dust, and renovation residue can add to the load. Cleaning targets these accumulations, restoring clear pathways so equipment spends less effort delivering the same comfort.

From a health perspective, the goal is to reduce recirculated particles and potential irritants. While ducts are only one piece of indoor air quality, they interact with filters, coils, and supply diffusers that influence what you breathe. Evidence-based maintenance focuses on sources: fix gaps that draw in attic or crawlspace dust, seal loose joints, and ensure filters fit snugly in their housings. As part of a holistic plan, duct cleaning supports these steps by removing settled material that could otherwise be dislodged during high fan speeds. For homes with shedding pets or nearby construction, inspections often justify more frequent attention.

There is also a performance angle. Any obstruction—nests, heavy lint mats, or leftover job-site grit—can raise resistance in the system. Increased resistance may push blowers toward higher energy use and can aggravate noise as air fights through constrictions. Real-world gains depend on baseline conditions: cleaning a relatively clean system won’t transform bills, but clearing obvious blockages and sealing leaks can reduce waste. Practical expectations include smoother airflow, fewer dust puffs when the fan starts, and a cleaner look at supply and return points. Consider duct work as part of a broader tune-up that includes filters, coil cleaning, and sealing—together, the benefits are more noticeable.

Useful starting checks include:

– Look for visible dust streaks at grilles and on nearby walls, a clue of leakage or poor filtration.

– Test airflow at several registers with a simple vane anemometer to spot weak branches.

– Note odors on startup; persistent smells may indicate microbial growth on coils or in drip pans rather than in ducts.

Tools and Materials: Inspection Gear, Agitation Devices, Collection Systems, and Filtration

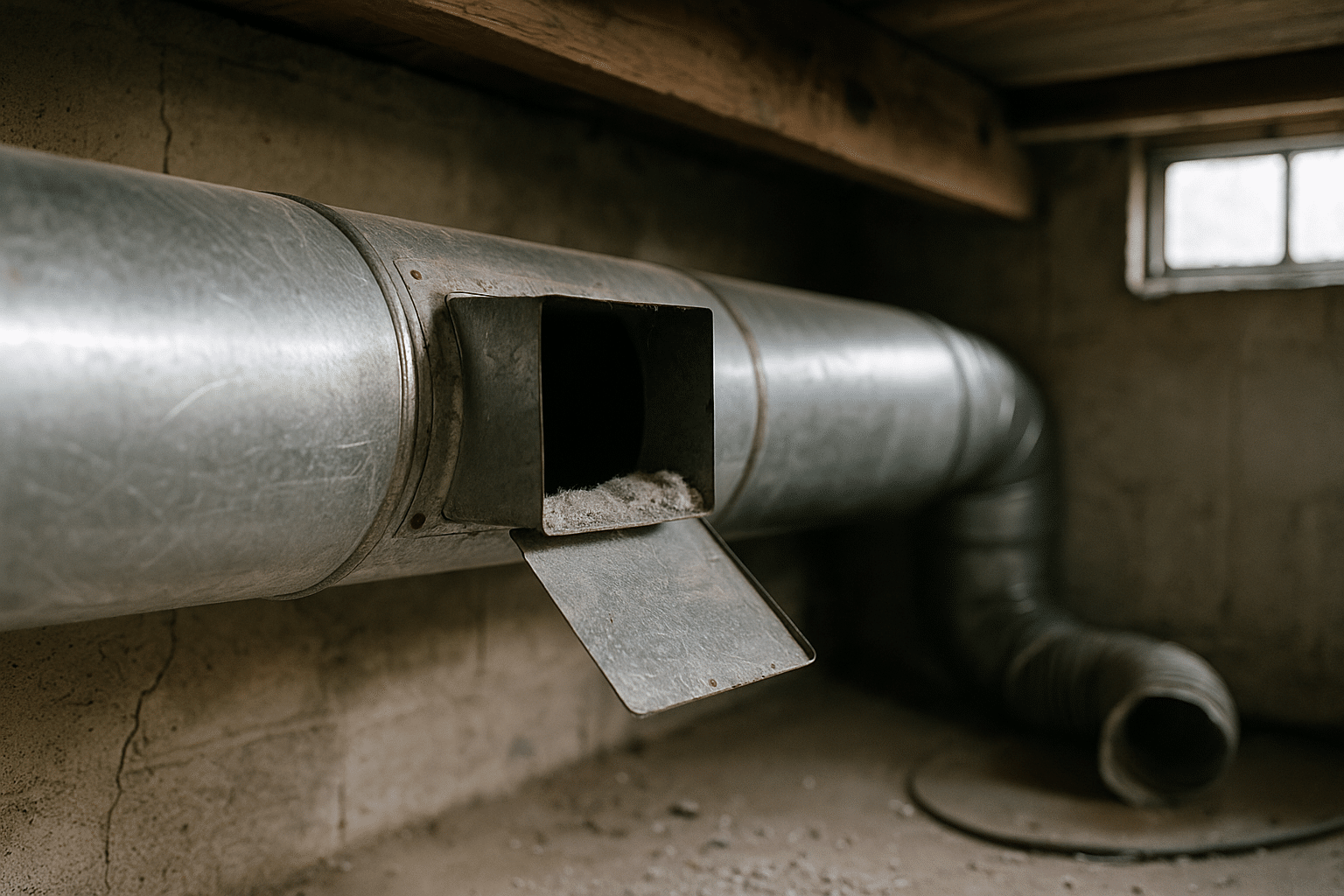

Successful duct cleaning blends seeing, loosening, and capturing. Inspection tools verify what needs work and help you avoid damaging sensitive components. Simple solutions include a high-lumen flashlight and mirror to peek past grilles. More advanced options involve small inspection cameras with flexible leads to confirm branch conditions and identify matted debris, torn flex duct, or insulation sloughing. A basic differential pressure gauge can hint at restrictions across filters or coils, helping you distinguish duct issues from other constraints in the air handler.

Agitation breaks debris loose so it can be collected. For rigid metal ducts, rotary brushes with soft bristles can scrub without scoring the surface, while compressed-air whips move along bends to shake dust out of corners. Flexible ducts and internally lined ducts need gentler methods; excessive force can damage liners or delaminate flex walls. For tight spaces, hand brushing at grilles and trunk access points is often safer. The guiding principle is simple: use the least aggressive tool that still dislodges buildup, matching the method to the duct material, diameter, and condition.

Collection is the backbone of cleanliness. A high-flow negative-pressure machine connected to the trunk line draws airborne debris into a sealed container. Units with high-efficiency particulate filtration capture fine particles, reducing the chance of redistribution. When a dedicated machine isn’t available for small DIY tasks, a shop vacuum with a high-efficiency filter and a tight hose connection at access points can help, though capacity and filtration are typically lower. The collection system’s hoses and seals should be tight to maintain negative pressure; leaks at joints reduce capture efficiency and can spread dust.

Consumables and accessories round out the kit:

– Tight-fitting filters for the air handler to prevent bypass during and after cleaning.

– Duct access panels or removable plugs to create service openings without leaving gaps.

– Tape and mastic for resealing seams, plus gaskets for access covers.

– PPE including a particulate respirator, gloves, and eye protection to keep workers safe.

– Drop cloths and adhesive floor film to protect interiors during containment.

Finally, keep a documentation kit—labels, a marker, and a phone camera—to record before-and-after conditions. Photos of trunk interiors, branch takeoffs, and grille backs provide a simple quality check and inform future maintenance decisions.

Step-by-Step Cleaning Workflow: Preparation, Containment, Cleaning, and Verification

A repeatable process minimizes mess and delivers verifiable results. Preparation begins with a system survey: note duct materials (metal, flex, or lined), layout (trunk-and-branch, radial, or plenum-fed), and access limitations. Confirm power is off to the air handler and set thermostat controls to prevent accidental starts. Protect interior spaces with drop cloths, and clear a path to the mechanical area. Identify suitable access points near the air handler and at distant branches; where none exist, install service openings designed for resealability.

Containment comes next. Attach the negative-pressure collection hose to the main trunk and verify suction at test ports. Seal nearby registers temporarily to concentrate airflow from the farthest branches back toward the collector. This creates a controlled airflow that carries loosened debris to the capture unit. If you’re working in a shared building, post a simple notice near the thermostat and return grille to avoid surprises, and open a nearby window slightly to maintain fresh makeup air during the process.

Cleaning proceeds from the furthest branch back to the air handler. Insert the appropriate agitation tool—soft rotary brush for rigid metal, gentle air whip for complex bends—and advance steadily. Limit dwell time in flexible ducts; instead, make multiple light passes to reduce risk. For each branch, confirm that dislodged material is moving toward the trunk by feeling for increased suction or using a handheld particle counter near the collector exhaust. At grilles, hand brush both the visible surfaces and the backside of blades, where sticky films often cling. If biological growth is suspected elsewhere in the system, focus on source control—clean coils and drain pans—rather than applying harsh chemicals inside ducts, which can leave residues and may not address the root cause.

Verification builds confidence. Replace any temporary seals, remove the collection connection, and reseal access panels with gaskets and mastic. Visually inspect with a camera at several random points, aiming for clean metal or intact liner without loose debris. Restore power, install a clean, appropriately rated filter, and run the fan. Check airflow at several registers and compare notes to pre-clean readings. Record what was done, where access points were added, and any defects discovered—crushed flex runs, missing insulation, or leaky joints—so they can be corrected in follow-up work.

Quick checklist for repeatability:

– Shut down power and protect spaces.

– Establish negative pressure and seal nearby registers.

– Agitate branches from far to near with matched tools.

– Capture, reseal, and visually verify.

– Document readings, photos, and repairs needed.

Safety, Quality, and Environmental Stewardship: Doing the Job Responsibly

Safety starts with personal protection and extends to the building and its occupants. Even if visible dust looks harmless, fine particles can irritate eyes and airways during agitation. Wear a particulate respirator, gloves, and eye protection. Avoid loose clothing around moving tools. Before cutting any access, confirm the absence of concealed wiring or refrigerant lines with a locator or careful visual inspection. For gas appliances, ensure combustion appliances have been shut down and that any pilot lights are considered before creating airflow changes that might affect draft.

Quality is about more than shiny metal. Overly aggressive brushing can damage liners or tear flex duct, creating new problems like fiber shedding or air leaks. Use the gentlest effective method and verify progress periodically rather than “powering through.” Sealing is another quality lever; a cleaned system that still leaks pulls in dust from attics or crawlspaces and wastes energy. Reseal disturbed joints with mastic, and ensure access panels close against intact gaskets. Finally, choose filters that fit tightly and meet your system’s airflow and filtration needs—loose or overly restrictive filters either bypass debris or strain the blower.

Environmental stewardship is practical and cost-aware. Collect and bag debris before leaving the work area, and avoid venting dusty air outdoors without proper filtration. If you encounter materials that look suspicious—friable insulation or unknown residues—pause and consult guidelines for handling; do not disturb potentially hazardous materials. When possible, select cleaning methods that minimize chemical use; physical removal and source control typically offer durable improvements without adding compounds to the airstream. Used filters, rags, and disposable PPE should be disposed of according to local regulations, and reusable tools should be cleaned so they don’t transfer contaminants to the next job.

Communication rounds out responsible practice:

– Let occupants know when noise or airflow changes will occur.

– Share before-and-after photos to demonstrate results.

– Provide a simple care sheet with filter change dates and inspection reminders.

– Note any conditions outside the cleaning scope that merit repair, such as crushed ducts or missing insulation.

By treating safety, quality, and environmental impact as a single thread, you reduce risk, enhance outcomes, and keep the building’s air distribution reliable long after the equipment is switched back on.

DIY or Professional: Costs, Red Flags, and a Maintenance Roadmap

Choosing between DIY and professional service hinges on layout complexity, contamination level, and your tools and time. DIY can work for targeted tasks—cleaning grilles, vacuuming accessible return boxes, installing access plugs, and lightly brushing short, straight branches. It’s a reasonable approach in smaller systems with mostly rigid metal ducts and visible debris near access points. However, long runs, multiple floors, dense branch networks, internal liners, or flexible ducts routed through cramped spaces often favor professional equipment and experience. A pro can create stronger negative pressure, reach farther into bends, and verify results with better imaging and airflow measurements.

Costs vary widely by region, building size, and scope. DIY expenses typically involve a few tools and consumables—access panels, tape and mastic, protective coverings, and upgraded filtration. Professional projects factor in labor hours, machine setup, multiple access points, and verification. Avoid unusually low quotes that promise sweeping results in minutes; thorough work takes time. Sensible indicators of quality include a defined process, clear containment plans, evidence-based decisions about where to create access, and documentation you can keep.

Watch for red flags:

– Promises of dramatic energy savings without inspecting the system.

– Reluctance to show photos of actual conditions or to explain the workflow.

– Heavy use of chemical fogging as a cure-all instead of source control and physical removal.

– Cutting access holes without resealing with proper panels and gaskets.

Build a maintenance roadmap that keeps cleaning in context. Start with filtration: choose a filter that your blower can handle, and change it on schedule to minimize bypass and dust loading. Inspect grilles and the first few feet of duct annually; if you see fresh buildup soon after filter changes, look for leaks that pull dirty air from unconditioned spaces. Consider targeted cleaning every three to five years in typical homes, sooner if renovations, wildfire smoke, or pet populations increase dust loads. Complement duct work with coil and drain maintenance, sealing of exposed joints, and airflow balancing to address comfort complaints.

Conclusion: For homeowners and facility managers alike, a measured approach works. Inspect first, match tools and methods to materials, contain and capture, and verify with photos and readings. Some jobs are well within DIY reach; others pay for themselves through professional thoroughness and saved time. Either way, the outcome you’re aiming for is simple: cleaner pathways, steadier airflow, and a system that supports healthy, comfortable spaces without drama.