Agricultural Machinery 1.14: Features, Uses, and Maintenance Essentials

Outline of the article:

– Defining Agricultural Machinery 1.14: scope, standards, and why it matters now

– Core Features and Configurations: powertrains, hydraulics, guidance, and attachments

– Practical Uses Across Farm Types: arable, livestock, orchards, rice, and smallholdings

– Maintenance Essentials and Lifecycle Costs: preventive routines and total cost of ownership

– Decision Framework and Future Outlook: choosing equipment and staying future-ready

Defining Agricultural Machinery 1.14: Scope and Significance

Agricultural machinery 1.14 refers to a contemporary benchmark of farm equipment capabilities: safe, efficient power units and implements harmonized with precision tools and data-ready components. Think of it as a practical “dot release” that rolls up incremental improvements—cleaner engines, better hydraulic control, smarter sensors—into a clear bundle farmers can evaluate and deploy. The label does not replace local regulations or standards, but it points to a level of performance and interoperability that fits today’s production realities: tighter labor markets, unpredictable weather, and an increasing need to document inputs and outcomes.

At its core, 1.14-readiness touches three dimensions. First, mechanical robustness: tractors in the 30–400 horsepower range, transmissions matched to field tasks (from simple manual-shuttle to continuously variable), and driveline protection that tolerates sudden loads. Second, control fidelity: responsive hydraulics and power take-off (PTO) that deliver steady flow and speed to planters, sprayers, loaders, and mowers. Third, data-aware operation: position correction, implement mapping, and machine-health alerts, all designed to keep operators informed without adding complexity during peak seasons.

Why does this matter? Because efficiency gains at the machine level scale across acres and hours. A modest improvement in fuel burn—say 5–10% through better gearing, tire inflation, and engine optimization—can offset part of rising input costs. Industry field studies commonly report that fuel represents a substantial share of operating expenses for field work, and downtime during planting or harvest has outsized impact on revenue. Safety also improves with rollover protection systems, better lighting, and clearer operator interfaces that reduce missteps under time pressure. In short, the 1.14 mindset helps equipment deliver consistent power, predictable control, and actionable information—three pillars of reliable throughput.

Consider the outcomes growers often seek:

– Higher pass-to-pass accuracy so inputs land exactly where intended

– Lower maintenance surprises through routine checks and early warnings

– Better traction management to preserve soil structure and fuel

– Flexible implement compatibility to switch tasks quickly without rewiring the farm day

Core Features and Configurations in 1.14-Ready Fleets

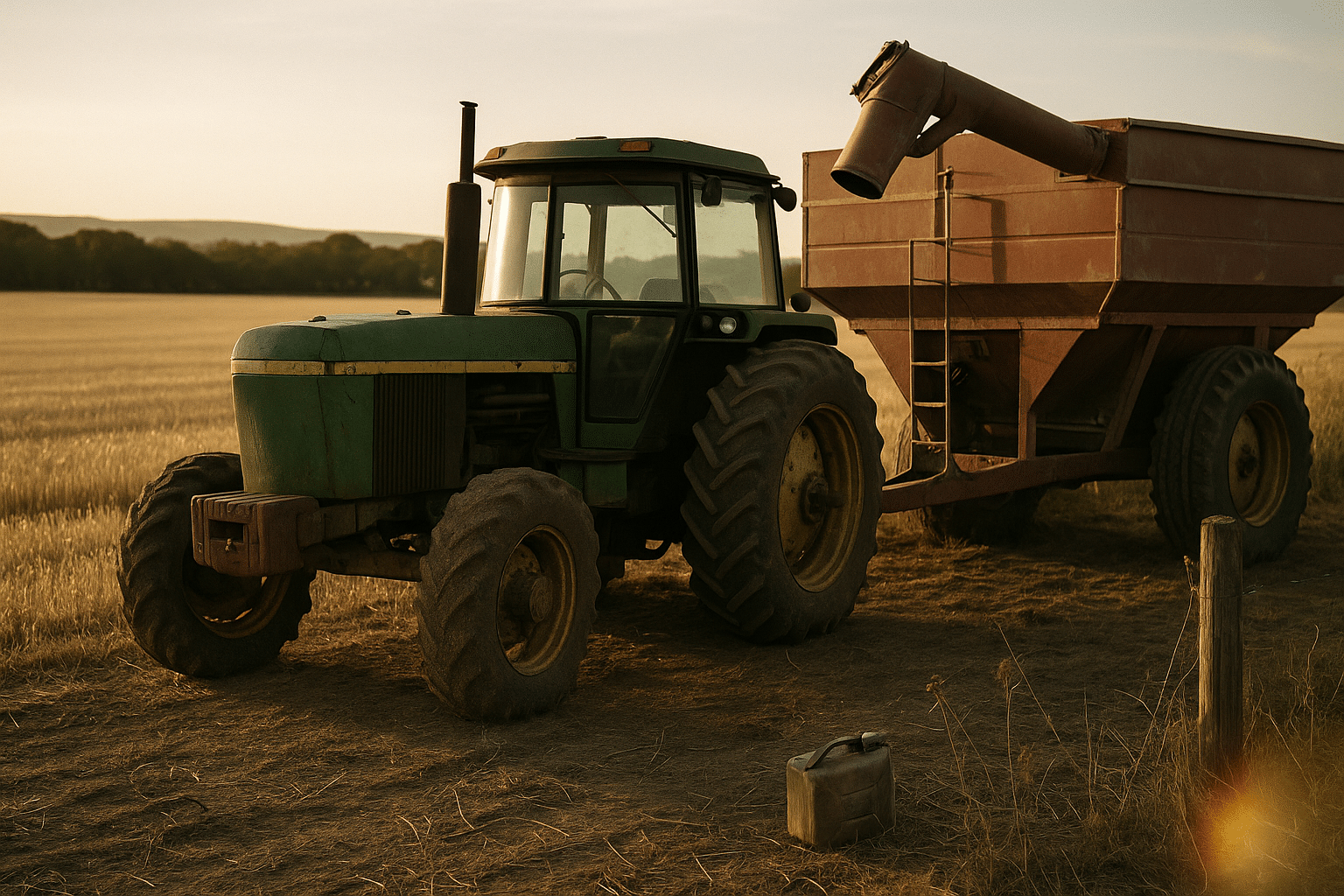

Machinery combinations under the 1.14 umbrella typically start with the power unit: tractors or self-propelled platforms sized to the heaviest implement used during peak fieldwork. For many mixed operations, a 90–150 horsepower tractor remains a versatile anchor, handling loaders, mid-width mowers, small square balers, and modest tillage. Larger arable enterprises might deploy 200–350 horsepower units for deep ripping, broad planters, or heavy grain carts. Transmission choice influences precision and fuel economy: powershift offers sturdy step changes for draft, while continuously variable drives can maintain target ground speed at optimal engine rpm, especially useful for planting and spraying.

Hydraulic capacity is another critical lever. Modern implements may demand multiple rear remotes and robust flow rates to operate fans, downforce systems, or fold mechanisms. Flow figures vary, but ensuring a margin above combined implement requirements prevents sluggish functions and heat buildup. PTO configurations at 540 or 1,000 rpm accommodate different implements; some machines provide both speeds, improving flexibility. On the ground, tire versus track setups balance soil protection and transport practicality. Wider, lower-pressure tires or central inflation systems can reduce compaction, while track units shine on soft or hilly fields at the cost of more complex undercarriages.

Cab environments have evolved from simple shelters into work hubs. Visibility lines, suspension seats, and low-glare instruments reduce fatigue during long windows. Guidance capability ranges from sub-meter accuracy suitable for broad tasks to sub-inch repeatability using local corrections for banded fertilizer or strip-till. Equipment using standardized implement communication (for example, ISO-based protocols) helps unify displays and controllers, reducing the tangle of separate screens. Telematics can sync work logs, fuel use, and maintenance timers back to a farm office or cloud service, enabling oversight without hovering over every field gate.

Attachments and implement compatibility shape actual productivity. Loader-ready frames speed bale handling; front hitches allow pairing front mowers and rear conditioners for one-pass cuttings. Planter modules benefit from singulation monitoring and sectional control that reduces overlap in irregular fields. Sprayers gain from variable rate application and boom stability aids that keep nozzles at the correct height over uneven terrain. Together, these features create a toolkit, not just a machine, minimizing changeover time and errors where hours are precious.

Key configuration questions before purchase:

– What is the heaviest, most power-hungry task you perform annually?

– Which implements need simultaneous hydraulic circuits and PTO?

– How accurate must guidance be for your inputs and field shapes?

– Will tire, dual, or track setups protect soil while meeting transport limits?

Practical Uses Across Farm Types and Scales

Arable operations rely on machinery cadence: prepare the seedbed, plant on time, protect crop health, harvest efficiently. In small grains, a medium-power tractor partnered with drill and sprayer provides the backbone. For corn or oilseeds, the emphasis shifts to planters with row-by-row control, sidedress rigs that match rows exactly, and high-clearance sprayers for late-season passes. Harvest brings combines, grain carts, and augers into a choreography where throughput and logistics determine how smoothly a crop moves from field to storage without bottlenecks.

Livestock-focused farms align machinery with forage cycles. A nimble loader tractor keeps bedding and feed moving daily, while mower-conditioners, tedders, and rakes set the pace for hay quality. For silage, timing is everything: choppers, wagons, and packing tractors must match capacity so that the bunker seals promptly, preserving nutrients. Livestock producers often value cold-start reliability, mud performance, and easy attachment changes because chores cannot wait on better weather.

Specialty and perennial crops carry unique demands. Orchards and vineyards need narrow-width tractors with high hydraulic finesse to operate pruners, mowers, and sprayers between tight rows without removing limbs or trellises. Hillside stability, low branches, and variable canopy densities encourage careful selection of weight distribution and tire profiles. Horticulture and greenhouse operations prize compact utility machines that can lift pallets, power small implements, and maneuver in confined spaces; electric or hybrid options may appeal where ventilation is sensitive and run-times are short and frequent.

Rice systems and flooded paddies demonstrate how environment reshapes machinery. Higher-flotation tires or half-tracks, corrosion-conscious maintenance, and debris-resistant cooling systems become essential. In terraced landscapes, braking stability and engine braking control reduce downhill risk. Smallholder contexts, prevalent in many regions, favor modular tools: a single power unit with multiple quick-attach implements spreads investment across tasks while remaining serviceable with basic tools. Cooperative models—shared equipment or custom operators—help access higher-spec machines only when the job requires them.

Use-case highlights that guide selection:

– Match implement widths to field access, headlands, and transport routes

– Consider mowing and spraying under tree canopies or between trellis wires

– Confirm safe operating angles for slopes and wet ground

– Balance purchase price against seasonal hire or cooperative sharing

Maintenance Essentials, Reliability, and Lifecycle Economics

Reliability is rarely an accident; it is the cumulative outcome of small, regular actions. A 1.14-ready maintenance plan starts with hour-based service intervals and escalates to seasonal deep checks. Daily walkarounds—checking oil, coolant, belts, hoses, tire pressures, and lug torque—catch issues before they scale. Air filters demand special attention in dusty harvests; a partially clogged filter drags fuel economy and power, and repeated cleaning beyond the manufacturer’s guidance can damage pleats, so scheduled replacement matters. Greasing pivots and universal joints is cheap insurance, especially on loader frames and hitch points that live under heavy cyclic loads.

Cooling systems deserve a calendar reminder. Radiator fins and charge-air coolers accumulate chaff; a gentle blowout (not a direct high-pressure blast) preserves fin integrity while restoring heat exchange. Hydraulic health hinges on clean oil and correct viscosity. Sampling oil at set intervals can reveal early wear metals; catching a problem then is far cheaper than replacing a pump and downstream components. Electrical systems benefit from secured grounds and tidy harness routes that avoid pinch points; weatherproof connectors and dielectric grease prolong sensor reliability in rain, mud, and fertilizer mist.

Storage between seasons multiplies payback. Draining water traps, topping tanks to reduce condensation, stabilizing fuel, and disconnecting or maintaining batteries curb off-season decay. Implements should be washed, dried, and stored under cover where possible; bearings last longer when protected from dust and dew. Keeping a maintenance log provides traceability for warranty, resale, and continuous improvement—knowing which component failed and when informs future parts stocking and operator training.

Lifecycle economics transforms maintenance into strategy. Total cost of ownership (TCO) bundles depreciation, interest, insurance, storage, fuel, lubricants, parts, and labor. A simple approach tallies annual machine hours and assigns per-hour costs to each category; comparing this to expected revenue per hour (for custom work) or estimated yield benefit (for in-house operations) clarifies return. Even small enhancements—automatic headland turns that trim overlap, tire inflation that cuts rolling resistance, or predictive alerts that avoid a peak-season failure—can shift the TCO curve meaningfully. Practical checklist to keep TCO in line:

– Schedule services by hours and seasons, not just dates

– Standardize fluids and filters across machines where feasible

– Stock fast-moving wear parts before harvest and planting

– Use telematics or logs to flag abnormal fuel or temperature trends

Decision Framework and Outlook: Choosing and Staying Future-Ready

Choosing machinery under the 1.14 banner is part engineering, part economics, and part timing. Start by mapping your critical path: which weeks in the year truly define success? If planting needs to occur in a narrow weather window, prioritize the tractor-planter pair, guidance accuracy, and reliability features that lower rework risk. If forage quality dictates animal performance, focus on mower-conditioning capacity and the wagons or balers that keep pace. In constrained budgets, one highly capable power unit with quick couplers and multi-speed PTO can cover many roles better than several underutilized platforms.

Compatibility remains a smart hedge. Confirm that implements and displays share common connectors and data formats; avoid isolated systems that require bespoke adaptors or lock you into specific peripherals. Ask for the hydraulic flow, PTO torque, and radial tire load charts that match your implements at your soil moisture and slopes. Test demonstrations on actual fields if possible; traction, turning radius, and visibility on paper can differ from real-world behavior among terraces, trees, and narrow gates.

Sustainability and regulations shape the horizon. Cleaner engines reduce local emissions around homes and barns; matched implements that reduce overlap also lower overall input use. Variable-rate systems, when calibrated, help target fertilizer to zones that respond, sometimes trimming costs while maintaining yield. Electrification is emerging in smaller frames and stationary tasks such as pumps or augers; hybrids and energy-recovery concepts are appearing in heavier classes. Autonomy continues to advance from guidance and headland automation toward supervised swarm units for specific tasks, but robust safety and clear operating protocols remain the anchor of adoption.

Practical decision points to close the loop:

– Rank your top three tasks by time sensitivity and power demand

– Size the power unit for the hardest job, then confirm it will downshift to lighter tasks efficiently

– Choose accuracy levels that match input costs and field shapes

– Plan for maintenance access, parts availability, and training

Conclusion: Turning 1.14 readiness into everyday productivity means buying machines that fit your fields, operators, and seasons. Favor clear specifications, interoperable controls, and a maintenance plan you can sustain when the calendar is tight. Your payoff is not only higher output per hour, but calmer days when weather closes in and the job still gets done.