Flat Roof Renovation: Costs, Materials, and Step-by-Step Guide

Project Outline and Planning Essentials

Before rolling out new membrane or calling a crew, sketch a clear roadmap. Here’s the outline this article follows, and the order you can mirror for a real project: – Assess condition, moisture, and structure. – Choose materials aligned to climate, traffic, and budget. – Build a cost plan and contingency. – Confirm permits, codes, and insurance. – Schedule around weather and lead times. – Execute a layer-by-layer install. – Inspect, test, and document. – Maintain with seasonal checkups.

Why planning matters: a flat roof is a system, not a single layer. Everything works together—deck, vapor control, insulation, membrane, flashing, and drainage. Codes commonly call for positive drainage, often targeting at least 1/4 inch per foot (about 2%) of slope to move water to scuppers or internal drains. If your roof holds water longer than 48 hours after rain, budget for a tapered insulation package or crickets to nudge water off the field. Standing water magnifies UV stress, accelerates seam fatigue, and invites algae that can hide early damage.

Start with a thorough assessment. Note cracks at parapets, loose counterflashing, soft spots in the deck, failing sealant around penetrations, and a history of leaks. Where feasible, a moisture survey (core samples or infrared by a qualified provider) helps distinguish between repairable surface wear and saturated insulation that must be removed. If you suspect structural issues or heavy rooftop loads—HVAC units, pavers, or snow loads—consult a structural professional before adding layers. Flat roofs may look simple, but a few millimeters of trapped moisture can freeze, expand, and delaminate assemblies over a single winter.

Define requirements early: – Climate priorities such as high UV, frequent hail, or coastal exposure. – Roof use, from light foot traffic for maintenance to regular access for equipment. – Energy goals and local code R-value targets. – Budget tolerance for a tear-off versus an overlay. – Warranty expectations and documentation needs. With these pinned down, you can match materials to performance, sequence work to the forecast, and set a realistic contingency (10–15% is common) for hidden deck repairs or drain rebuilds. Planned well, renovation becomes a controlled, stepwise upgrade rather than a scramble after the next storm.

Materials Compared: Membranes, Lifespans, and Use Cases

Flat roof materials differ in chemistry, installation method, durability, and cost. Knowing where each shines helps you avoid overpaying for features you don’t need or underbuilding in a harsh climate. Common options include EPDM, TPO, PVC, modified bitumen, built-up roofing, and liquid-applied coatings. Typical installed pricing can range from about $3 to $12 per square foot depending on region, roof size, access, and detailing. Lifespans are broad estimates because quality of installation and maintenance often matter as much as the product itself.

EPDM (synthetic rubber) is known for flexibility and weathering tolerance. – Typical lifespan: 20–30 years with good maintenance. – Installed cost: roughly $4–$8 per square foot. – Strengths: large sheets, fewer seams, cold-weather elasticity. – Considerations: dark surfaces can increase heat gain unless paired with ballast or coatings; adhesives and seam tapes require careful prep. TPO (thermoplastic polyolefin) offers reflective surfaces that can reduce heat absorption. – Lifespan: commonly 15–25 years, varying by formulation and exposure. – Cost: about $5–$9 per square foot. – Strengths: heat-welded seams and high reflectivity. – Considerations: requires precise welding; quality varies by product generation and installer skill.

PVC (polyvinyl chloride) is valued for chemical resistance and heat-welded seams. – Lifespan: about 20–30 years in many climates. – Cost: around $7–$12 per square foot. – Strengths: weldable detailing at corners and penetrations; reflective surface. – Considerations: compatibility with certain roof materials must be checked; can stiffen with age. Modified bitumen blends asphalt with polymers, available in torch, cold-applied, or self-adhered formats. – Lifespan: typically 15–25 years. – Cost: roughly $4.50–$8.50 per square foot. – Strengths: robust puncture resistance, layered redundancy. – Considerations: torch applications require strict fire safety; seams need diligent detailing.

Built-up roofing (BUR) layers bitumen and reinforcing plies, sometimes topped with gravel. – Lifespan: about 20–30 years. – Cost: around $6–$11 per square foot. – Strengths: multiple plies create redundancy, good ballast options for UV protection. – Considerations: heavier system; logistics and smell may be a factor. Liquid-applied membranes (acrylic, polyurethane, silicone) create monolithic surfaces. – Lifespan: typically 10–20 years. – Cost: about $3–$7 per square foot for restoration contexts. – Strengths: seamless detailing, effective for overlays where substrate is sound. – Considerations: sensitive to surface prep and weather windows; curing times matter.

Match material to context: – Hot, sunny climates often benefit from reflective TPO or PVC. – Cold climates value EPDM’s flexibility and robust seam prep. – Heavy foot traffic may lean toward modified bitumen or protected assemblies with walkway pads. – Chemical exposure (kitchens, labs) points to PVC. – Tight budgets and sound substrates can suit liquid restorations. Choose performance over trend; a well-installed, well-detailed system usually outlasts a premium membrane with rushed workmanship.

What Drives the Price: A Transparent Cost Breakdown

Renovation cost is more than a membrane number. Plan around line items you can control and those you can’t. Typical contributors include removal, deck repair, insulation, tapering, membrane and flashing, accessories, labor, permits, and site logistics. Ballpark figures vary by market, but the ranges below help frame decisions and contingencies.

Common cost components: – Tear-off and disposal: about $0.75–$2.00 per square foot, more if multiple saturated layers must go. – Deck repairs: localized fixes can be a few hundred dollars; wide replacement can add $2–$5 per square foot. – Insulation: each incremental R-10 may add roughly $1.50–$4.00 per square foot depending on material and thickness. – Tapered insulation/crickets: about $1–$3 per square foot of roof area. – Membrane and flashing: see material ranges; complex parapets and penetrations add labor time. – Drains and scuppers: $300–$900 each for rebuilds or replacements. – Safety and access: edge protection, hoisting, and debris chutes can add meaningful cost on multi-story sites. – Permits and inspections: often $100–$800, based on jurisdiction and scope.

Two simplified scenarios for a 1,500 sq ft roof: – Overlay restoration, sound substrate: basic surface prep, a liquid-applied system, minor flashing upgrades. Estimated total: $7,000–$12,000, reflecting limited demolition and quick staging. – Full tear-off with new tapered insulation and single-ply: removal, deck patching, R-value upgrade, tapered package, welded membrane, new metal edges, and drain rebuilds. Estimated total: $18,000–$32,000, driven by labor and material volume. These ranges shift with access constraints, regional labor rates, and project timing.

Think long-term, not just upfront. A reflective, well-insulated roof can trim cooling loads in warm climates, while higher R-values cut heat loss in cold regions; many properties see heating or cooling bills drop by 5–15% when moving from an underinsulated, dark surface to a code-compliant, reflective assembly. Factor life-cycle cost: divide total installed cost by expected service years to compare options on an annualized basis. Add a 10–15% contingency to absorb surprises without stalling the schedule. Transparent budgeting reduces change-order friction and keeps the project advancing even when hidden damage shows up beneath the old membrane.

Step-by-Step Renovation: From Assessment to Leak Testing

A disciplined sequence prevents small issues from turning into expensive callbacks. Step 1: due diligence. Walk the roof, map defects, check slope, probe blisters, and trace staining back to suspect details. Note ponding areas and clogged drains. Photograph everything; clear documentation anchors scope and helps compare bids. If feasible, schedule a moisture scan to target saturated zones for removal. Step 2: plan logistics. – Safety: fall protection, perimeter flags, ladder tie-offs. – Access: staging areas, material hoisting, debris path. – Weather: choose a stable forecast and avoid tight curing windows.

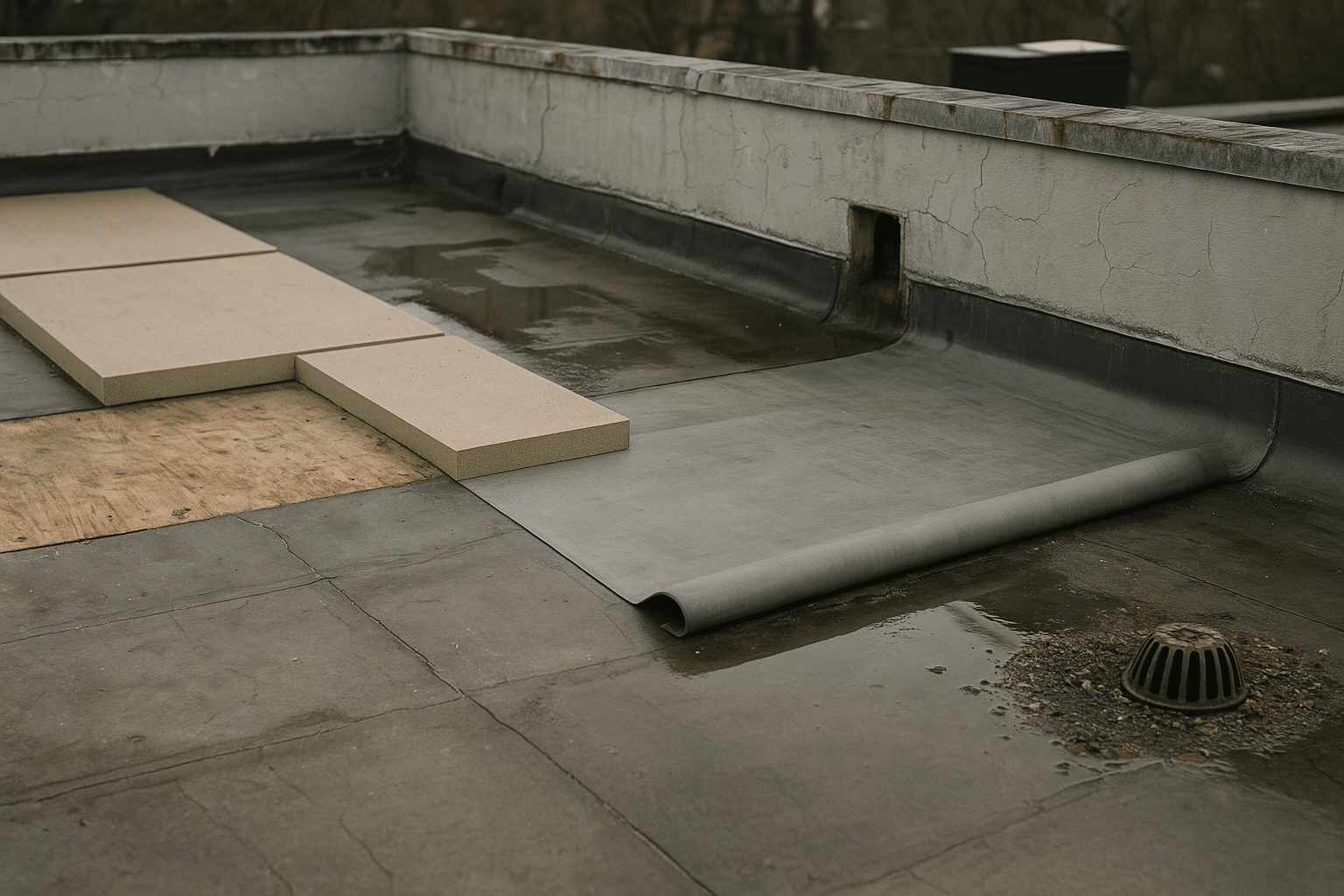

Step 3: remove damaged layers. Cut and remove wet insulation and failed patches; keep penetrations protected during open-roof conditions. Step 4: repair deck and establish vapor control as needed. Replace corroded metal decking or delaminated wood sheathing; prime as specified. Install a vapor retarder where interior humidity or climate requires it, coordinating seams with the insulation plan. Step 5: install insulation. Stagger joints, adhere or mechanically fasten per manufacturer instructions, and ensure continuous coverage around edges and penetrations. For ponding, add tapered boards to achieve positive drainage toward drains and scuppers.

Step 6: membrane installation. For single-plies, place sheets to minimize cross-seams, fasten or adhere per wind zone requirements, and weld or seam-tape with verified temperatures and dwell times. For modified bitumen or BUR, maintain correct asphalt or adhesive application rates and fully embed plies. Reinforce at corners, curbs, and transitions. Step 7: flashing and terminations. – Wrap penetrations with preformed or field-fabricated details. – Set metal edges with continuous cleats and sealant, then secure counterflashing. – Install strainers at drains and verify positive flow with water.

Step 8: quality control and testing. Conduct seam probes, pull tests where specified, and a methodical visual inspection around every curb and corner. Where structure allows, limited flood testing or electronic leak detection can validate watertightness; consult a professional if uncertain about added water load. Step 9: cleanup and documentation. Remove debris, label penetrations on the as-built plan, and record product data, batch numbers, and photographs. A clean, well-documented turnover reduces future troubleshooting time and supports warranty or insurance needs if a leak ever appears.

Conclusion: Maintenance, Risk Management, and Smart Next Steps

Renovation doesn’t end on the last day of installation; that’s the start of stewardship. Create a simple maintenance plan that fits your building. – Inspect in spring and fall, and after significant storms. – Clear leaves and debris from drains and scuppers. – Check terminations, pitch pockets, and sealant for movement. – Look for punctures along common footpaths and under equipment. – Document every visit with photos and brief notes. Small patches addressed early are far cheaper than chasing water that has traveled across insulation and into interior finishes.

Recognize warning signs. – Ponding that persists beyond 48 hours suggests drainage or slope issues. – Blistering, alligatoring, or membrane shrinkage around edges points to aging or incompatibility. – Rust at metal deck seams or soft wood indicates moisture beneath. – Staining below rooftop penetrations signals flashing or curb problems. If any of these show up, schedule a targeted inspection and budget for corrective work before damage spreads.

For owners and facility managers, the smartest move is aligning choices with the building’s purpose and climate. A light-colored, well-insulated assembly can cut heat gain in a sun-soaked region, while a durable, puncture-resistant surface is valuable where foot traffic is routine. Add walkway pads where technicians travel, and coordinate future add-ons—solar arrays, new HVAC platforms—so standoffs and curbs are integrated, not improvised later. Keep warranties, permits, and as-builts in one accessible folder; organized paperwork shortens downtime and speeds repairs.

Above all, treat the flat roof as a long-term asset. Plan thoroughly, select a material that honestly fits your needs, insist on meticulous detailing, and maintain it with brief, regular checkups. Do that, and your renovation becomes a reliable investment that protects interiors, moderates energy costs, and saves you from the uncomfortable surprise of drip buckets during the next storm.