Mastering the Art of Concrete Pouring: A Comprehensive Guide

Introduction to Concrete Pouring

Concrete pouring is a pivotal process in construction, forming the foundation of many structures, from buildings to bridges. The quality of the concrete pour can significantly impact the durability and safety of the finished structure, making it essential for construction professionals to master this skill. Concrete pouring involves a series of steps, each demanding attention to detail and adherence to best practices to ensure a successful outcome.

Understanding the nuances of concrete pouring is crucial for anyone involved in construction, whether you’re a seasoned professional or a DIY enthusiast. This guide aims to offer a comprehensive overview of the process, shedding light on the techniques, materials, and considerations that contribute to a successful concrete pour.

Preparing for the Pour

Preparation is key to a successful concrete pour. It begins with site assessment and preparation, where the area is cleared of debris, and the ground is leveled and compacted. This step ensures that the concrete will sit evenly and reduces the risk of cracking or settling later on.

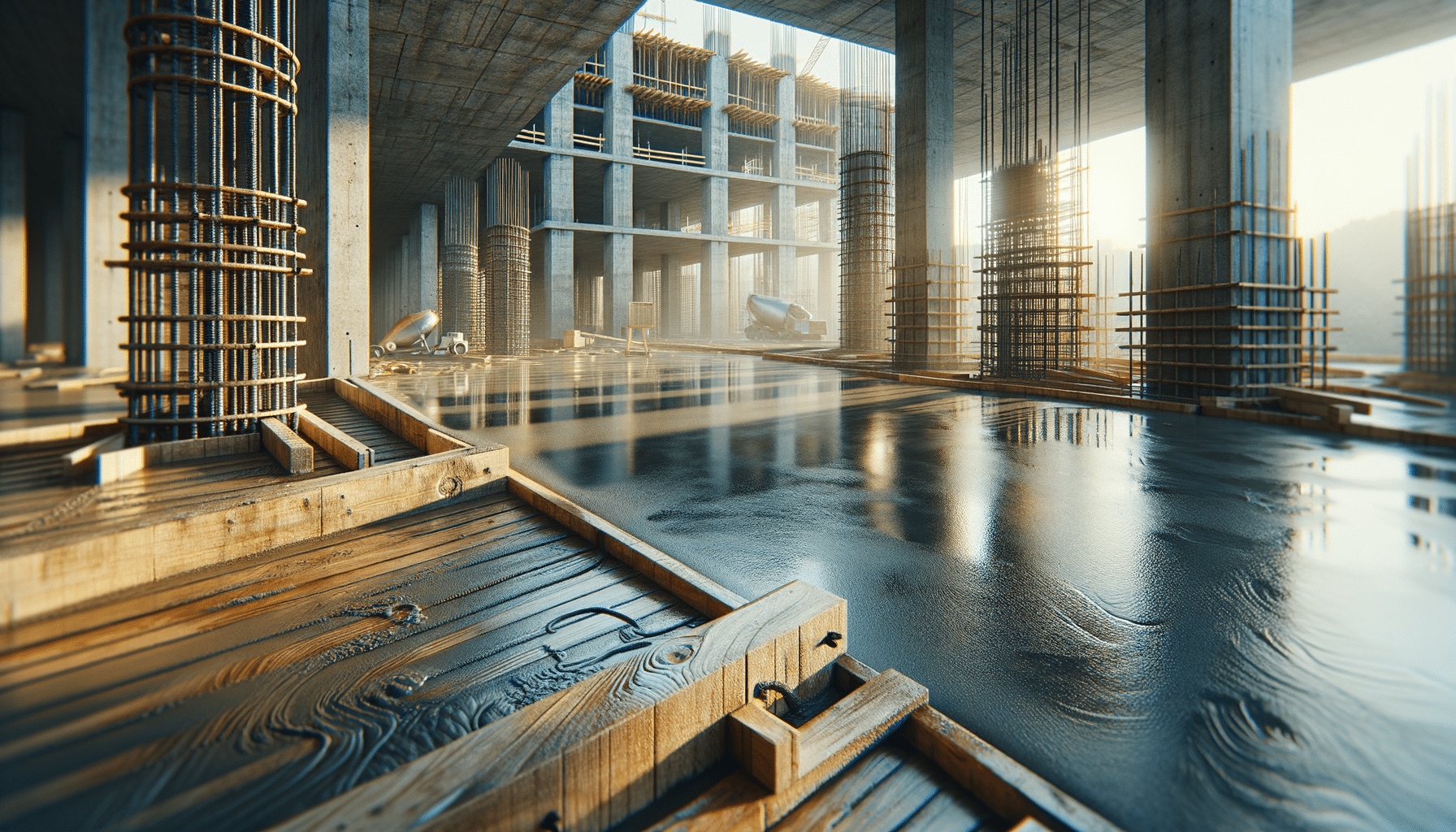

Next, formwork is constructed to shape the concrete and hold it in place until it sets. Formwork must be sturdy and precisely aligned to ensure the final structure meets design specifications. Materials for formwork can vary, but they often include wood, metal, or plastic, each offering different benefits depending on the project requirements.

Before pouring, it’s essential to consider the weather conditions. Concrete pouring should ideally be done in mild temperatures to prevent rapid drying or freezing, which can compromise the concrete’s integrity.

The Pouring Process

Once the site is prepared and the formwork is in place, the concrete mix is prepared. This involves combining cement, water, and aggregates (such as sand and gravel) in precise proportions. The mix must be consistent to ensure even setting and strength throughout the concrete.

The actual pouring process requires a steady hand and careful management. Concrete is typically poured in layers, with each layer being leveled and compacted to remove air pockets and ensure a smooth finish. The use of tools like vibrators can help to consolidate the concrete and improve its density.

Throughout the pouring process, it’s crucial to monitor the concrete’s consistency and adjust the mix as needed to accommodate changing conditions. This adaptability is what often separates successful pours from those that require costly repairs down the line.

Curing and Finishing

After pouring, the concrete must be allowed to cure, a process that ensures it reaches its maximum strength. Curing involves maintaining moisture in the concrete for a specific period, typically a week or more, depending on the mix and environmental conditions.

Finishing the concrete involves techniques like troweling, edging, and jointing to achieve the desired surface texture and appearance. Proper finishing not only enhances the concrete’s aesthetic appeal but also its durability and resistance to wear.

During the curing and finishing stages, it’s important to protect the concrete from external factors like rain, wind, or extreme temperatures, which can negatively affect the curing process and the final quality of the concrete.

Common Challenges and Solutions

Concrete pouring is not without its challenges. Common issues include cracking, which can occur due to improper curing or environmental stress. Using control joints can help mitigate this by allowing for natural expansion and contraction.

Another challenge is achieving the correct mix consistency. Too much water can weaken the concrete, while too little can make it difficult to work with. Precision in measuring and mixing is crucial to avoid these pitfalls.

Finally, weather conditions can pose significant challenges. Pouring in hot weather may require additional water or retarders to slow the setting process, while cold conditions might necessitate accelerators or insulation to aid curing. Being prepared to adapt to these conditions is an essential skill for any concrete professional.